Plastic Line Carrier 4" Condux 08030300

Plastic Line Carrier 4" Condux 08030300

Condux 08030300 Line Carrier 4", is a fast and efficient plastic carrier for fishing with high-speed blowers even in out-of-round duct and will travel over any minor obstruction that might be inside the duct.

Specifications:

Duct Size: 4" (102mm)

Maximum OD: 4.06" (103mm)

Cable Seal for Gulfstream™ 400 Condux 08761435

Cable Seal for Gulfstream™ 400 Condux 08761435

Replacement Cable Seal for Fiber Optic Cable Blowers are sold in pack of 4.

Cable Diameter: 1.05-1.13

These seals work the the appropriate Cable Venturi for the following blower models:

HD Blower

Deluxe Lightweight Blower

Mini-Blower/Pusher

Mounting Socket Side Mount Condux 08675138

Mounting Socket Side Mount Condux 08675138

The Condux Fiber Optic Cable Puller has a square mounting post 21⁄2" (64

mm) x 21⁄2" (64 mm). A female mounting socket is required for

stability during cable pulling operations.

TurboSlitter Cordless Drill Attachment Condux 08010220

TurboSlitter Cordless Drill Attachment Condux 08010220

TurboSlitter-Cordless Drill Attachment CONDUX 08010220

The TurboSlitter™ from Condux can easily split HDPE pipe with wall thicknesses ranging from 0.097 to 0.216 inches! Available in two styles, pneumatic and cordless drill attachment. The cordless drill attachment quickly adjusts to fit almost any rechargeable drill, 14-volt and larger. Save time and effort on the job with the TurboSlitter from Condux.

Can be used with a standard drill

Lightweight shear head for easy one-hand control

Alloy Capstan 7" GMP 10727

Alloy Capstan 7" GMP 10727

This general purpose capstan is used for a wide variety of pulling and hoisting applications. Cast from a high strength aluminum alloy for low weight.

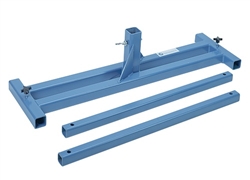

Fiber Optic Cable Puller Hitch Mount Condux 08675908

Fiber Optic Cable Puller Hitch Mount Condux 08675908

The Condux 08675908 Fiber Optic Cable Puller Hitch Mount attaches directly into a typical 2" (51 mm)

square Reese-type receiver and the cable puller mounts in a 21⁄2" (64 mm) square fixture. An adjustable

jack is included for added stability and height adjustment. Pulling loads must not exceed 800 lbs. (3,559 N).

Remote Mounting Stand Condux 08675115

Remote Mounting Stand Condux 08675115

The 08675115 Remote Mounting Stand allows positioning of the cable puller well away from the power source. Easy to set up, the unit is both sturdy and compact.

12"x9" Capstan Wheel Condux 08675213

12"x9" Capstan Wheel Condux 08675213

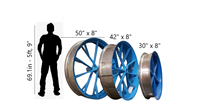

To conform to the many specifications of fiber optic cable available, and to offer more cable pulling capabilities, Condux offers several sizes of capstans that fit the Condux Fiber Optic Cable Puller.

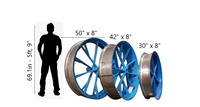

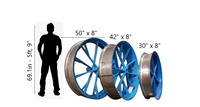

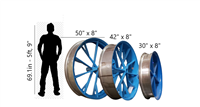

30" x 8" Capstan Wheel Condux 08675430

30" x 8" Capstan Wheel Condux 08675430

To conform to the many specifications of fiber optic cable available, and to offer more cable pulling capabilities, Condux offers several sizes of capstans that fit the Condux Fiber Optic Cable Puller.

42" x 8" Capstan Wheel Condux 08675436

42" x 8" Capstan Wheel Condux 08675436

To conform to the many specifications of fiber optic cable available, and to offer more cable pulling capabilities, Condux offers several sizes of capstans that fit the Condux Fiber Optic Cable Puller.

30" Slip Clutch Capstan 200 lbs Condux 08760030-02

30" Slip Clutch Capstan 200 lbs Condux 08760030-02

Slip Clutch Capstans from Condux are designed to mount directly on a

bayonet style winch drive shaft. A factory preset torque limiter

prevents pulling tensions from exceeding 200 pounds. If the preset load is reached, the capstan will "slip"

and discontinue rotating. High strength aluminum and steel construction

ensures product durability and cable protection.

30" Slip Clutch Capstan 300 lbs Condux 08760030-03

30" Slip Clutch Capstan 300 lbs Condux 08760030-03

Slip Clutch Capstans from Condux are designed to mount directly on a

bayonet style winch drive shaft. A factory preset torque limiter

prevents pulling tensions from exceeding 300 pounds. If the preset load is reached, the capstan will "slip"

and discontinue rotating. High strength aluminum and steel construction

ensures product durability and cable protection.

50"X 8" Capstan Wheel Condux 08675220

50"X 8" Capstan Wheel Condux 08675220

To conform to the many specifications of fiber optic cable available, and to offer more cable pulling capabilities, Condux offers several sizes of capstans that fit the Condux Fiber Optic Cable Puller.

30" Slip Clutch Capstan 400 lbs Condux 08760030-04

30" Slip Clutch Capstan 400 lbs Condux 08760030-04

Slip Clutch Capstans from Condux are designed to mount directly on a

bayonet style winch drive shaft. A factory preset torque limiter

prevents pulling tensions from exceeding 400 pounds. If the preset load is reached, the capstan will "slip"

and discontinue rotating. High strength aluminum and steel construction

ensures product durability and cable protection.

Portable 13HP Hydraulic Power Pack Condux 08675702

Portable 13HP Hydraulic Power Pack Condux 08675702

This portable power source is matched perfectly to the requirements for the Condux Fiber Optic Cable Blower and Puller. Utilizing a small footprint, the 13hp Power Pack features a variable flow switch (from 5gpm to 8gpm) to ensure that every job can be covered with just one machine.